The large-scale die-casting industry of non heat treated aluminum alloys and integrated aluminum alloys in China presents a trend of high-quality and rapid development

China's non heat treated aluminum alloy and aluminum alloy integration

The large-scale die-casting industry presents a trend of high-quality and rapid development

The large-scale die-casting industry presents a trend of high-quality and rapid development

Author: Jiang Yujing

Aluminum alloy plays an important role in the global community's response to the challenges brought by climate change, the achievement of the "dual carbon" goal, and the journey towards sustainable human development. This is mainly attributed to the characteristics of aluminum alloy, such as light weight, high strength, corrosion resistance, good ductility, easy processing, non-magnetic, impact spark free, low-temperature brittleness, non toxicity, strong heat dissipation, good conductivity, good impact absorption, weldability, nuclear radiation resistance, and high recycling efficiency. Due to its excellent properties, aluminum materials have been widely used in fields such as aviation, aerospace, automotive, machinery manufacturing, shipbuilding, and modern industry. Especially in modern transportation, new energy vehicles, major equipment and other fields, integrated heat free die-casting aluminum alloy materials have become the trend of the world's die-casting aluminum alloy industry.

The Invention History of Aluminum and Aluminum Alloys

In the global development process of aluminum and aluminum alloys, there are epoch-making milestones that leave a deep impression on people: in 1808, the laboratory electrolytic reduction of metallic aluminum; In 1888, the industrial production of primary aluminum was achieved through the use of molten salt electrolysis method; In 1890, the world's earliest aluminum copper alloy was invented, making primary aluminum a structural material and becoming a reality; In 1908, the electrical aluminum alloy 1050 was invented and made into steel core aluminum stranded wire, pioneering the field of high-voltage remote transmission; In 1914, aluminum alloy die-casting was put into commercial operation and rapidly developed with the development of the automotive industry and the invention of cold chamber die-casting machines; In 1943, Alcoa invented 6063 alloy and 7075 alloy, ushering in a new era of high-strength aluminum alloys; In 1965, Alcoa invented A356 cast aluminum alloy, which became a classic cast alloy aluminum.

Since the 1980s, aluminum alloys have gradually been applied in various fields such as industry, military, technology, aerospace, transportation, machinery manufacturing, and power and electrical appliances; Especially in the new century, thousands of aluminum alloys have been developed worldwide to meet the needs of various fields. Aluminum plays a crucial role in the lightweight and modern development of human production and life.

The integrated die-casting non heat treated aluminum alloy industry chain in China is showing a rapid development trend

In recent years, China's non heat treated aluminum alloy materials and aluminum alloy integrated large-scale die-casting industry have shown a trend of high-quality and rapid development. The technology of integrated large-scale die-casting aluminum alloy materials has reached the world's advanced level and can fully meet the technical quality requirements of integrated large-scale die-casting.

Firstly, China has established a complete and advanced aluminum alloy production and processing system, with a complete range of aluminum alloy production categories and the largest production scale in the world. According to incomplete statistics, there are nearly 3100 aluminum alloy casting enterprises in China with an annual production capacity of approximately 21 million tons; There are about 2000 aluminum alloy die-casting enterprises with an annual production capacity of about 14 million tons; The production of aluminum alloy die-casting has increased from 149000 tons in 1990 to 7.55 million tons in 2022, with an average annual growth rate of 13.05%.

The second is the improvement of the independent knowledge innovation system and the rapid enhancement of innovation capabilities. According to data from Baiteng.com and Zhiyan Consulting, from 2008 to 2022, China's integrated die-casting patent applications showed a rapid upward trend, with a total of 237 patent applications. Among them, 2021 reached a peak in nearly 20 years, with 40 patent applications; In 2022, the number of patent applications for integrated die-casting in China was 32. With the development of new energy vehicles and Tesla's mass production of integrated die-casting technology in Model Y, domestic new energy vehicle enterprises, die-casting enterprises, equipment/mold manufacturing enterprises, and aluminum alloy casting enterprises are continuously increasing their R&D investment in integrated die-casting, establishing high starting, modern R&D institutions and professional R&D teams, and carrying out good in-depth cooperation in production, education, and research, further promoting the rapid application and development of integrated die-casting technology in China.

Third, the world's most advanced progressiveness integrated heat free aluminum alloy die casting industry is booming. For the automotive industry, integrated die-casting of car bodies has excellent advantages: it can improve the overall safety of the car body, reduce the workload of various component inspections and acceptance, improve the efficient and stable productivity of cars, and reduce comprehensive production costs by 20% to 30%. The integrated large die cast aluminum alloy body is lightweight, saves energy consumption, and has high value for recycling after the vehicle is scrapped. Therefore, China has established an overall high-speed development pattern in the integrated heat free aluminum alloy die-casting industry, from raw material research and development and production, equipment manufacturing, mold manufacturing, to large-scale modern production and continuous innovation. In the upstream of the integrated die-casting industry chain, there are mainly material suppliers, equipment manufacturers, and mold manufacturers. Large enterprises in the non heat treated aluminum alloy material industry include Lizhong Group, Aluminum Corporation of China, Nantong Hongjin, Suzhou Huijin, etc. At the same time, universities and enterprises such as Tsinghua University and Shanghai Jiao Tong University are also conducting comprehensive research and development of heat free aluminum alloy new materials. Among them, LDHM-02 independently developed by Lizhong Group AlSi7MnMg、 Low carbon recycled LZ-1 alloy and THLZ alloy material jointly developed with Tsinghua University have formed a product series. Equipment manufacturing enterprises mainly include Lijin Technology, Haitian Metal, Yizhimi, etc; Mold manufacturing enterprises mainly include Saiweida, Zhenzhi, Guangzhou cavity, etc; Large aluminum alloy die-casting enterprises mainly include Wencan Co., Ltd., Tuopu Group, Guangdong Hongtu, Meilixin, Aikedi, etc; The main host manufacturers include Tesla, BYD, Ideal, NIO, Xiaopeng, Huaren Yuantong, Geely Jike, FAW Hongqi, Changan and many other new energy vehicle manufacturing companies. China has formed the world's most competitive and complete integrated large-scale aluminum alloy die-casting industry chain without heat treatment.

Fourthly, the equipment level is becoming larger and more intelligent, gradually achieving high-quality and high-efficiency automated production. According to incomplete statistics, by the end of 2022, China will have built an annual production capacity of 8 million large tonnage integrated die-casting machines, with a series of integrated ultra large die-casting machines of 6000T, 6100T, 6600T, 6800T, 7000T, 7200T, 8800T, 9000T, 9200T, and 12000T, totaling about 81 units/set. There are currently about 55 large-scale integrated die-casting machines of various models under construction, and the annual production capacity of integrated die-casting will reach 14.5 million units. At the same time, the production line achieves artificial intelligence control and efficient production.

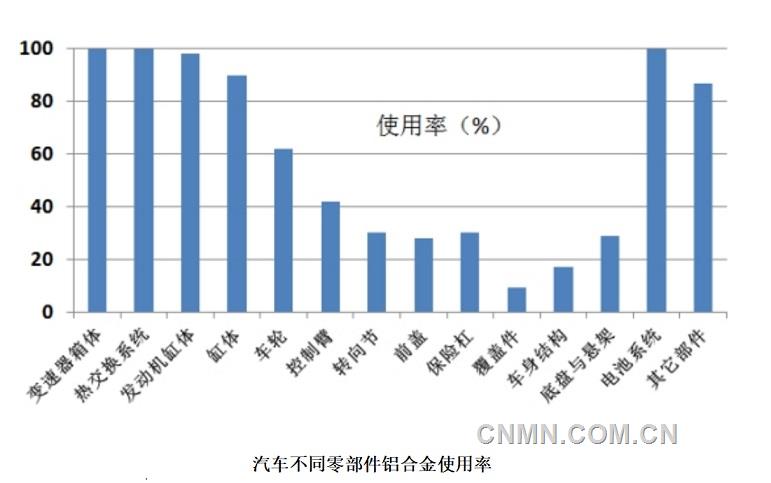

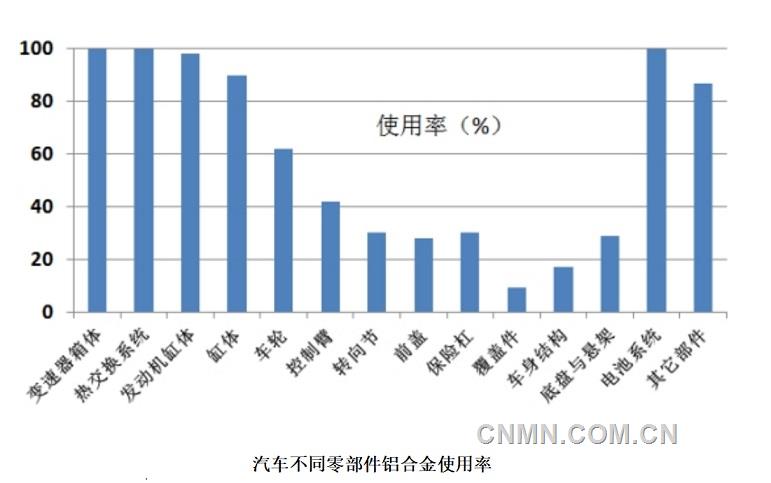

The fifth is that the market is showing a continuously growing prosperous scene. Aluminum alloy has a wide range of applications in automobiles, with components such as power and transmission systems, body and exterior systems, heat exchange systems, and wheels all made of aluminum alloy materials.

Aluminum alloy usage rate of different automotive components

With the development of automotive lightweighting, the rapid growth of aluminum alloy applications in the future will mainly focus on cover parts, body parts, and body structural components. The all aluminum body will increase from the current 4% to 18%, with an average annual compound growth rate of over 16%.

According to statistics from the China Association of Automobile Manufacturers, the production of new energy vehicles in China in 2022 was 7.058 million units, a year-on-year increase of 96.9%; The sales volume was 6.887 million units, a year-on-year increase of 93.4%. Against the backdrop of the rapid growth in sales of new energy vehicles and the continuous expansion of the use of large-scale integrated aluminum alloy die-casting parts, the integrated aluminum alloy die-casting industry will enter a stage of high-speed development.

In addition to its application in the important automotive field, the comprehensive rise of China's aerospace, electronic and electrical, major equipment, shipbuilding, artificial intelligence and other fields has also led to a significant increase in demand for aluminum alloy die-casting parts.

According to statistics from the China Association of Automobile Manufacturers, the production of new energy vehicles in China in 2022 was 7.058 million units, a year-on-year increase of 96.9%; The sales volume was 6.887 million units, a year-on-year increase of 93.4%. Against the backdrop of the rapid growth in sales of new energy vehicles and the continuous expansion of the use of large-scale integrated aluminum alloy die-casting parts, the integrated aluminum alloy die-casting industry will enter a stage of high-speed development.

In addition to its application in the important automotive field, the comprehensive rise of China's aerospace, electronic and electrical, major equipment, shipbuilding, artificial intelligence and other fields has also led to a significant increase in demand for aluminum alloy die-casting parts.

Urgent issues to be addressed in promoting the development of China's non heat treated aluminum alloy material industry

In the context of high-quality and rapid development in the aluminum alloy die-casting industry, the author believes that we should have a clear understanding and scientific grasp of the objective problems that exist in the industry's development.

One is that industry management still needs further standardization. At present, there are still many small-scale, outdated, and inefficient "workshop style" aluminum alloy die-casting manufacturers in the aluminum alloy die-casting industry. The industry can optimize its structure and comprehensively enhance its high-quality development through policy guidance, structural adjustment, increased efforts to encourage industrial transformation and upgrading, strict control and supervision of product quality, strict market access system, and elimination of adverse competition.

Secondly, China's integrated aluminum alloy die-casting started relatively late, and there are problems such as limited information and excessive reliance on foreign standards in the selection of aluminum alloy materials. For example, Alcoa's C611 material is not strictly speaking a large-scale integrated heat free aluminum alloy material, but it has been applied in this field earlier. The chemical composition of C611 is not a patented technology, and the specific heat treatment process is the main reason for the patent being granted, and this patented technology has expired in February 2023; In recent years, a considerable number of aluminum alloy enterprises in China have adopted the method of applying patents for their product development. Due to the lack of independent research and development capabilities and innovation, this has resulted in a mixed market; More importantly, some large aluminum alloy enterprises in China with independent research and development capabilities have developed patented technologies for integrated heat free treatment aluminum alloy die-casting, such as many patented technologies from domestic enterprises and universities: CN202010018461.7、CN202010270476.2、CN202111558726.3、CN202210038413.3 、CN202210800086.0、CN202211709047 .6 Wait, not only does it have a unique chemical element composition that can enhance the performance of aluminum alloy materials, but it also has superior performance and advanced production technology; Therefore, the die-casting industry should boldly innovate independently, reduce costs and increase efficiency for enterprises, and contribute to the healthy and healthy development of China's integrated casting aluminum alloy material technology and heat free treatment large-scale die-casting industry.

Thirdly, in the integrated heat free aluminum alloy die-casting industry, private enterprises in China have taken the lead and made significant contributions to the development of the national economy. As is well known, the aluminum alloy casting industry accounts for approximately 25% of global primary aluminum consumption, especially in contemporary and future development. With the development of new energy vehicles, major equipment, aerospace, marine development and utilization, military, etc., the integrated aluminum alloy die-casting industry will play an important supporting role. State owned enterprises should also play an important role in realizing the great aspirations of building a strong country, benefiting the people, and benefiting humanity.

Fourthly, we must firmly support and encourage the development of independent intellectual property rights and brand innovation in China. The state, governments at all levels, and industry organizations should provide substantial support in terms of policies and practical actions, jointly resist behaviors that are not conducive to the healthy development of the market, increase efforts to encourage and support technological progress and brand innovation, and ensure the sustainable and high-quality development of China's casting aluminum alloy and aluminum alloy die-casting industry.

Fifthly, in the aluminum alloy die-casting industry and its application fields, we will firmly promote and actively adopt new die-casting aluminum alloy materials with higher quality and cost-effectiveness, reduce costs, promote high-quality development of the industry, continuously enhance the innovation capability and international market competitiveness of our country's industry, firmly root innovation and development applications in the motherland, establish the idea of benign development of the global market, and benefit all mankind with practical actions.

Fourthly, we must firmly support and encourage the development of independent intellectual property rights and brand innovation in China. The state, governments at all levels, and industry organizations should provide substantial support in terms of policies and practical actions, jointly resist behaviors that are not conducive to the healthy development of the market, increase efforts to encourage and support technological progress and brand innovation, and ensure the sustainable and high-quality development of China's casting aluminum alloy and aluminum alloy die-casting industry.

Fifthly, in the aluminum alloy die-casting industry and its application fields, we will firmly promote and actively adopt new die-casting aluminum alloy materials with higher quality and cost-effectiveness, reduce costs, promote high-quality development of the industry, continuously enhance the innovation capability and international market competitiveness of our country's industry, firmly root innovation and development applications in the motherland, establish the idea of benign development of the global market, and benefit all mankind with practical actions.

The development of the global automotive industry faces three major themes: energy conservation, environmental protection, and safety. According to experimental verification by relevant research institutions, reducing fuel consumption by 10% for gasoline passenger cars can reduce fuel consumption by 3.3%, and reducing fuel consumption by 15% can correspondingly reduce fuel consumption by 5%. Integrated heat free aluminum alloy die-casting strongly supports the sustainable development of the automotive industry; The development of the aerospace industry and the development and application of high-performance integrated aluminum alloy products will demonstrate their superior performance; In a series of major equipment application fields, integrated aluminum alloy die-casting also has great potential. The era of rapid and high-quality development of non heat treated aluminum alloy materials and integrated non heat treated aluminum alloy die-casting industry has arrived.